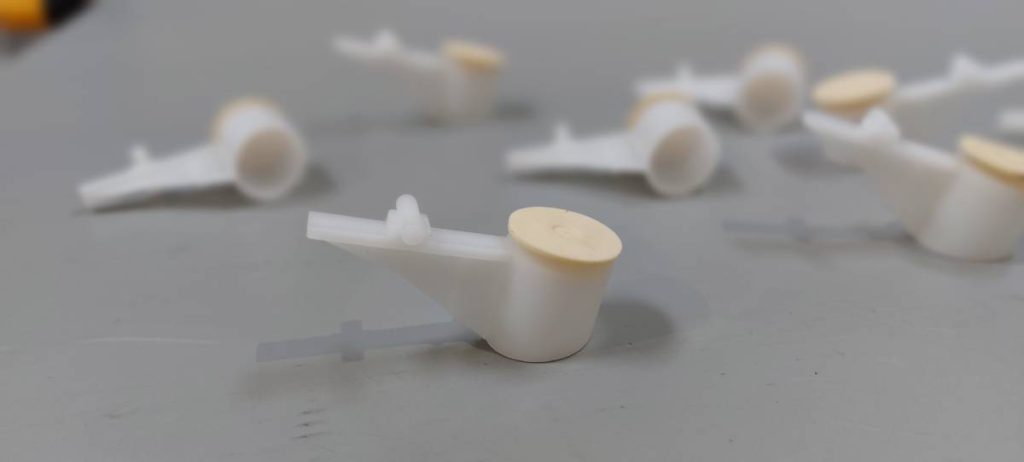

Bi-material injection molding, also known as two-component injection molding or overmold injection molding, is a manufacturing process that involves injecting two different types of material into the same mold to create a final part made of two distinct materials (material or coloring). This process makes it possible to combine the properties of two materials to obtain parts with specific characteristics, such as

stiffness, flexibility, durability or impact resistance.

Bi-material injection molding is commonly used to manufacture complex parts requiring specific properties in different areas of the part. For example, a tool handle can be manufactured with a hard plastic inner part for rigidity and a soft rubber outer part for grip comfort. This technique opens up a wide range of design possibilities and optimizes the product performance.

Expertise and quality await you at T.S.E. Why wait? Request a quote today.