Closing force from 50T to 650T

Injection volume from 168cm³ to 7300 cm³

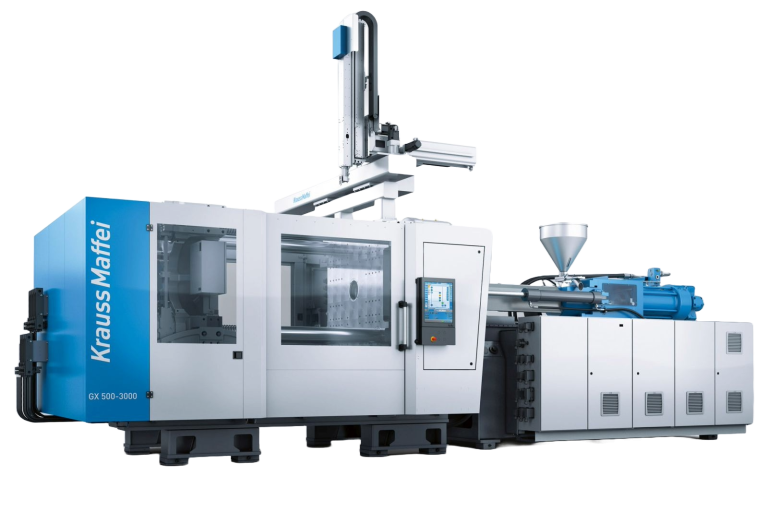

Our machinery includes 39 injection molding machines ranging from 50T to 650T, with injection volumes from 39 cm3 to 8588cm3. We also have 2 vulcanizing presses.

Closing force from 50T to 650T

Injection volume from 168cm³ to 7300 cm³

Closing force from 55T to 450T

Injection volume from 39cm³ to 1361 cm³

Closing force from 80T to 650T

Injection volume from 151cm³ to 8588 cm³

Cartesian robots for loading and unloading presses

Poly-articulated robots used for insert removal, assembly or machining operations

Poly-articulated robots used for insert removal, assembly or machining operations

Expertise and quality await you at T.S.E. Why wait? Request a quote today.

We have a total of 38 presses:

Yes, 80% of our machines are equipped with robots, whether Cartesian or polyarticulated, from SEPRO, KUKA and FANUC.

These robots are mainly used for loading and unloading presses, depositing inserts, as well as for assembly and machining operations. The type of operation depends on customer requirements.

Absolutely. Our machinery is recent, versatile and constantly renewed, enabling us to meet most of our customers’ needs.

We are moving towards fully electric presses. This transition enables us to support our customers while reducing our environmental impact, thanks to a 30% reduction in our annual electricity consumption.

Our entire environment has been designed with peripherals such as belts, grinders, desiccators and weight colorers, which guarantee the continuity of machine productivity.

Thanks to our fleet of presses equipped with the latest machines and robots, we are able to recycle our injection molding scrap and sprues. This is part of our eco-design approach to reducing our environmental impact.

We offer all our technical expertise in the design, production and fine-tuning of injection molds.

Yes, we work with a number of local, French and European partners to offer our customers a complete range of services.